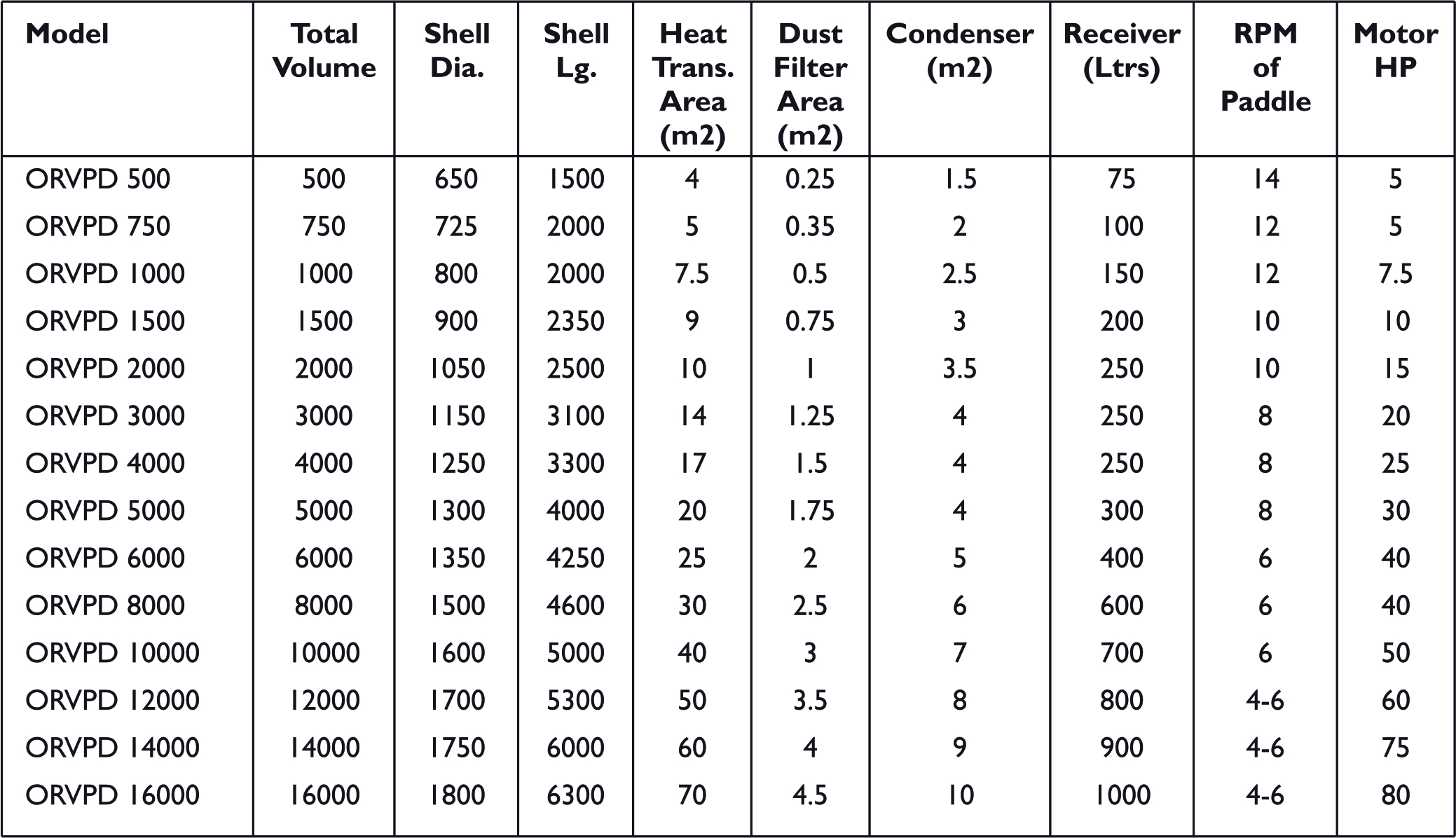

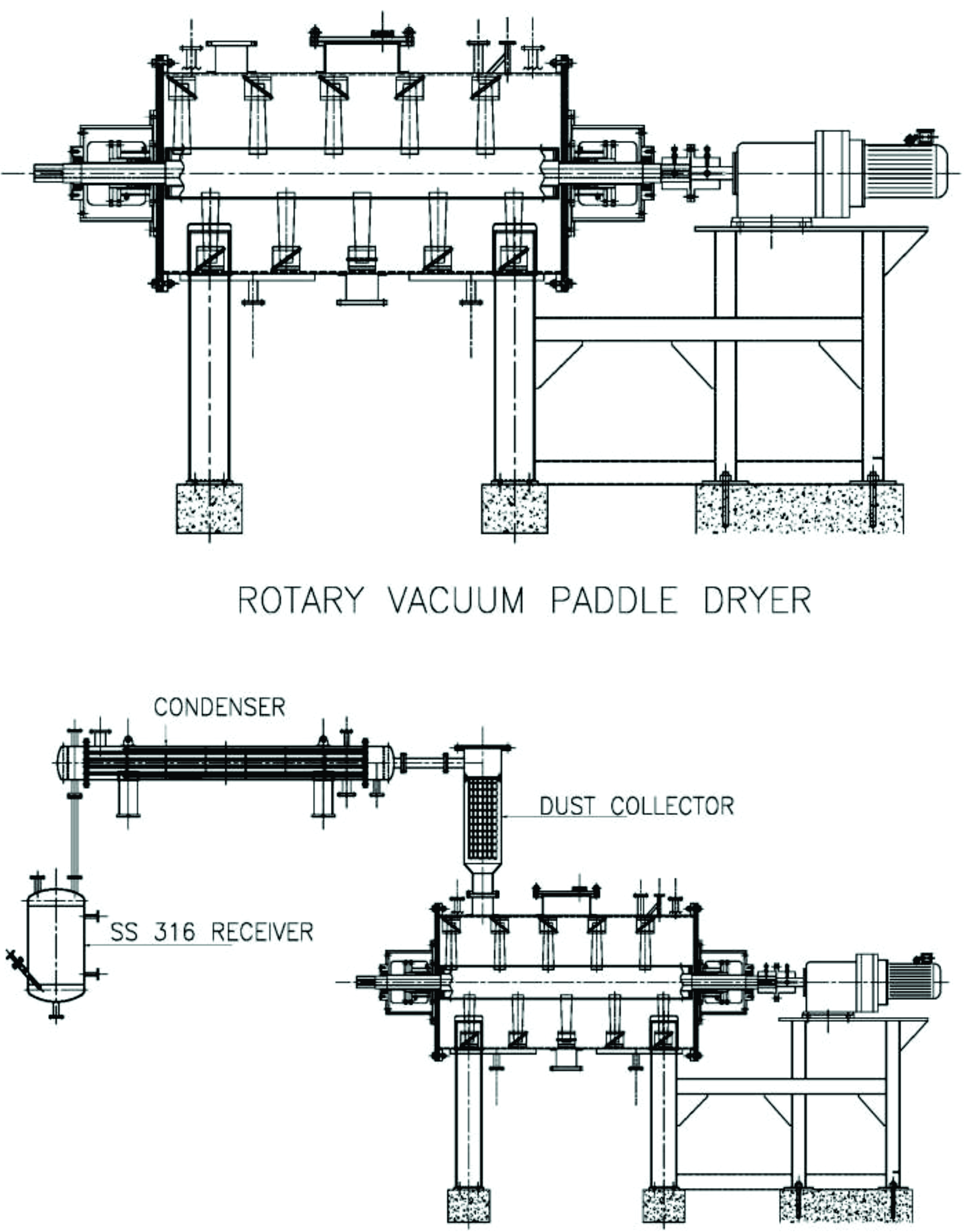

The Rotary Vacuum Paddle Dryer (RVPD) is a cylindrical vessel with Limpet/jacket for cooling or heating and a central agitator shaft having designed by scrapper blades. Scrape the entire internal surface of the dryer and continuously move and rotate in the shell. Rotary Vacuum Paddle Dryer (RVPD) offers a simple, clean and effective solution for vacuum drying at low temperature, Reaction, Crystallization, Solvent Recovery, Process commencing with Slurries or wet cake in batch operation carried out by heating and under vacuum.

Features