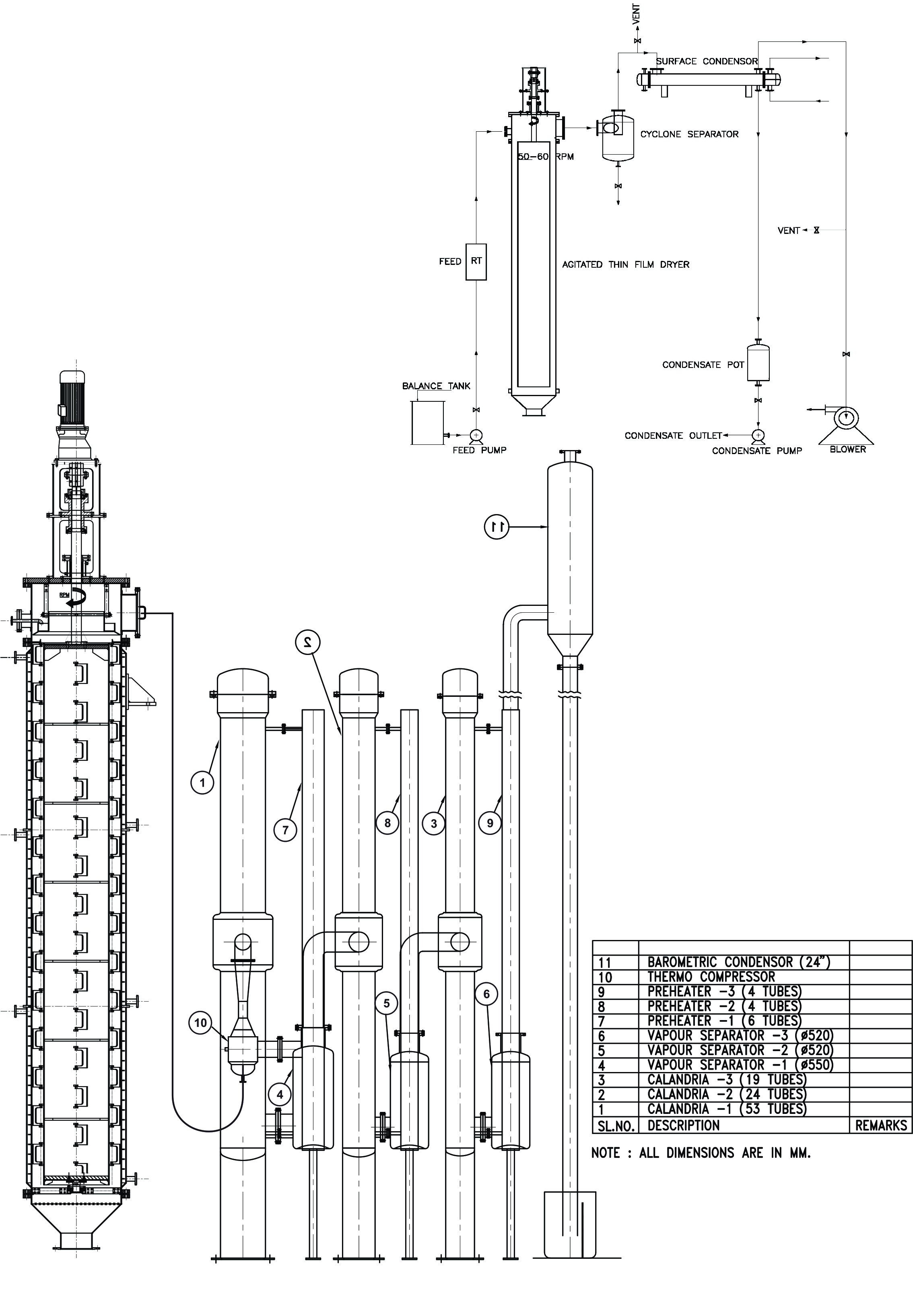

Agitated Thin Film Dryer (ATFD) for evaporation of water/solvents to make the concentrated liquid to dry powder or flakes Based on application either recovered solvent or dry product is important. Agitated Thin Film Dryer design is the ideal apparatus for continuous processing of concentrated material for drying. Normally Agitated Thin Film Dryer is consist of cylindrical shell, vertical body with heating jacket and rotor inside of the shell which is equipped with rows of pendulum blades all over the length of the dryer.

Our specially designed ATFD are highly-acquired by chemical, petrochemical, Pharmacy, textile and sugar industries.

The hinged type blades spread the wet feed product in a thin film over the heated on the surface. A highly agitated bow wave is formed in front of the rotor blades. The turbulence is increases the product passes through the clearance before entering a calming zone situated behind the blades. Where, the heat will transfer from jacket to main shell under the smooth agitation water/solvent will evaporate and liquid will convert to slurry, to cake and to dry powder or flakes. Generally agitated thin film dryer are mostly used into the process for industries to convert slurries, liquids and pastes to free flowing solids in continues operation.

Applications