Agitated filter is a cylindrical closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The advanced technology of agitation and hydraulics both are used in the equipment makes it versatile and user friendly. The wet cake reslurried and washed properly with water or solvents. Agitated nutsche filter dryer used in chemical, agrochemical, pharma and food industry. The ANFD is functionally safe and easy to operate. It can carry out different phase of process operation such as filtration, crystallization, extraction, discoloration, washing and Drying.

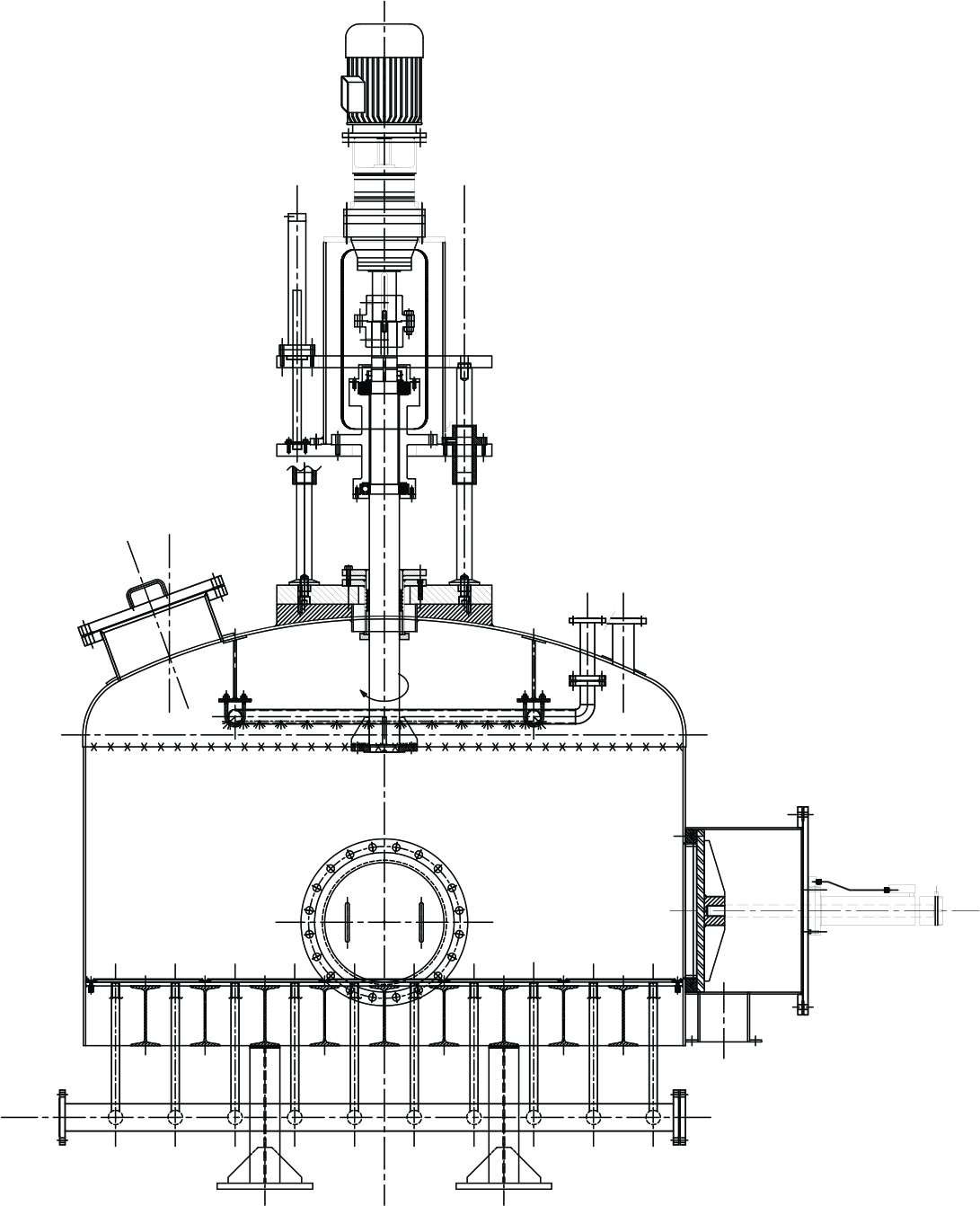

The ANFD Consists of cylindrical shell with top side dish and bottom side welded flat as per pressure vessel code. The stiffened support the welded flat and support mesh is provided under filter cloth to facilitate the flow of filtrate. Nozzle and Manhole also provide in the top dish and shell side discharge. valve also provided. The 'S' Shaped stirrer blades are mounted on the shaft. We also provide accessories of ANFD Such as Hydraulic Cylinder, Guide rod with bush, Hydraulic discharge valve, hydraulic Power pack, Control panel board etc.

Advantages