OME Engineers make Autoclaves are specially designed for different types of mixing Criteria. These types of Autoclaves built for large scale and these Autoclaves useful for longer life and withstand constantly temperature and pressure due to mixing condition Autoclaves agitator available with two types of sealing options like Mechanical seal and Gallan box. Our Autoclaves continuously work under the high pressure and temperature.

Autoclaves are manufactured as per ASME standard by using quality approved material. We also for various accessories like Blind Flanges, Required Gearbox and flameproof Motor etc. These Autoclaves are used in Chemical, petrochemical, Thermal industries etc.

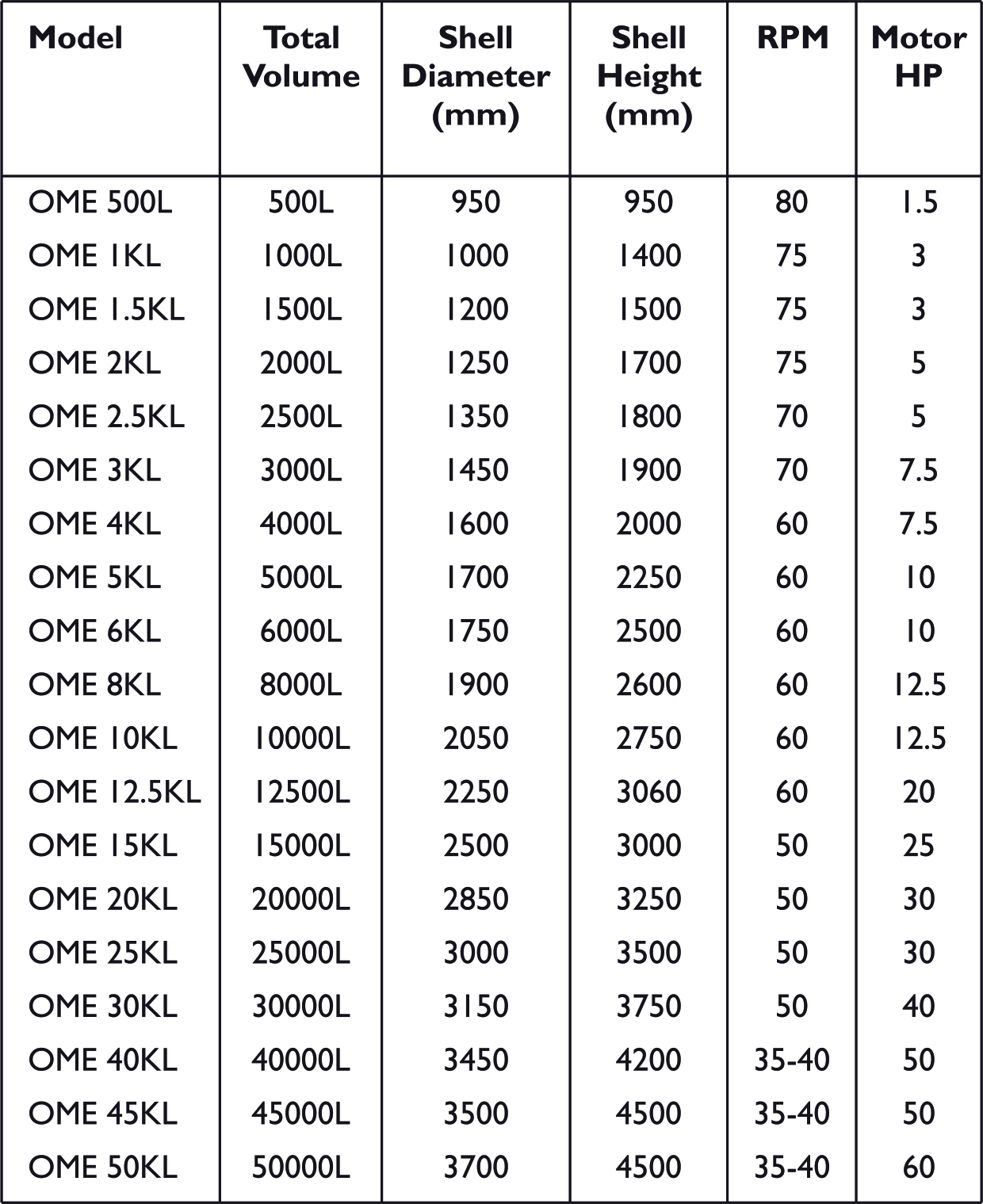

Design Capacity and Range